四川君见玮贸易有限公司

Sichuan Junjianwei Trading Co.

水泥内撑_水泥内撑厂家电话_水泥条生产厂家_君见玮辅材标件厂家

JUNJIANWEI

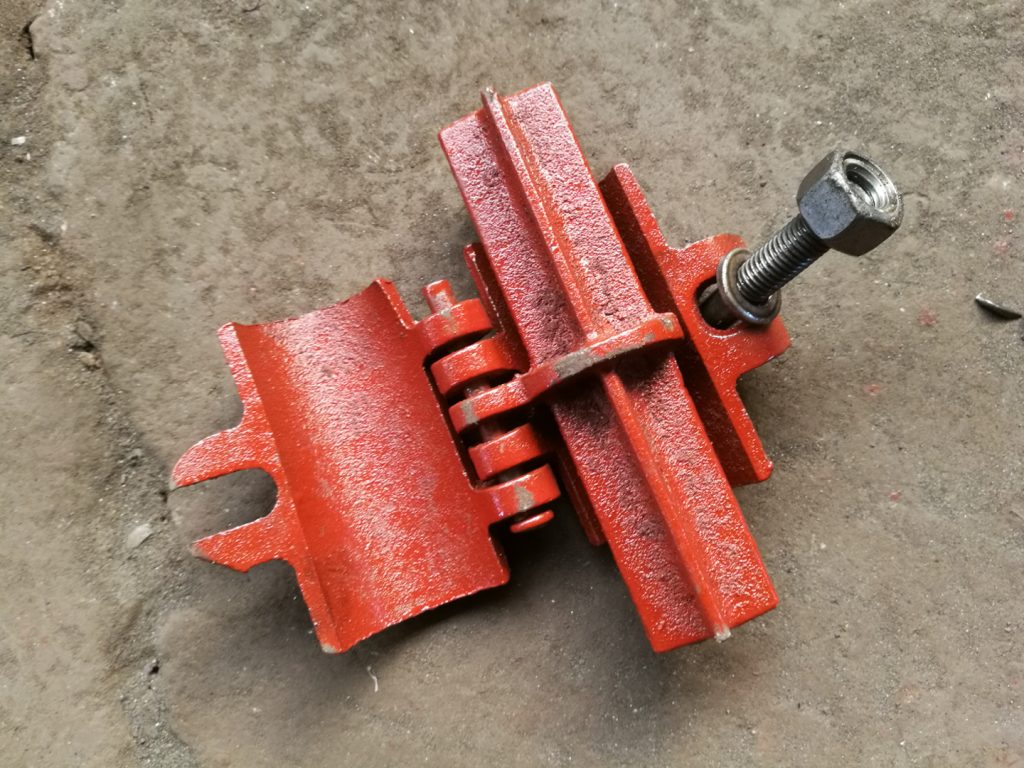

扣件

fastening

产品图片

Product image

产品适用方案

Product applicability plan

扣件的规范

Specification for fasteners

扣件是一种常见的连接元件,广泛应用于建筑、家具、机械等领域。为确保扣件的质量和使用效果,制定一套扣件的规范非常重要。下面是一份关于扣件规范的建议,包括扣件的材质、尺寸、制造工艺和质量检测等方面,以供参考。

一、扣件材质规范

1. 钢材规范:扣件一般采用优质碳素结构钢或合金钢制造,应符合国家相关标准。

2. 不锈钢规范:扣件也可以采用不锈钢材料制造,不锈钢的等级和组分应符合国家相关标准,可以选择304或316不锈钢材料。

二、扣件尺寸规范

1. 扣件的尺寸应符合国家相关标准和设计图纸要求。

2. 扣件的孔径和孔距应设计合理,方便安装和连接,孔径直径一般不应大于材料厚度的40%,孔距应根据扣件的使用要求进行合理设计。

三、扣件制造工艺规范

1. 材料切削加工:扣件的制造过程中,材料的切削加工要求精确,确保扣件的尺寸和形状精度,切削工艺应符合相关标准和要求。

2. 热处理:扣件的热处理应根据不同的材质和要求进行,以提高扣件的机械性能和使用寿命。

3. 表面处理:扣件的表面处理应使用合适的方法,如镀锌、喷涂等,以提高扣件的防腐蚀性能和美观度。

四、扣件质量检测规范

1. 外观检查:扣件应具有良好的外观,没有明显的裂纹、破损、变形等缺陷。

2. 尺寸检查:扣件的尺寸应符合设计要求,尺寸偏差应在允许范围内。

3. 材料检验:扣件的材质应符合相关标准,可以进行拉伸试验、冲击试验等检测。

4. 抗拉强度检测:扣件的抗拉强度应符合设计要求,检测时可以进行拉伸试验。

5. 盐雾试验:对于表面处理后的扣件,可以进行盐雾试验,以评估其耐腐蚀性能。

五、扣件标识规范

1. 扣件应有明确的标识,包括扣件类型、材质、尺寸等信息,方便使用者识别。

2. 标识应清晰可见,耐久性好,不易掉落或褪色。

六、扣件使用规范

1. 扣件的安装应严格按照设计要求进行,确保安装质量。

2. 扣件的使用应符合设计荷载要求,不得超过承载能力。

3. 扣件在使用过程中应定期检查,如发现问题应及时更换或维修。

以上是关于扣件的规范建议,通过制定一套科学合理的扣件规范,可以确保扣件的质量和使用效果,提高建筑、家具、机械等领域的安全性和可靠性。

Fasteners are a common connecting component widely used in fields such as architecture, furniture, and machinery. To ensure the quality and effectiveness of fasteners, it is very important to develop a set of fastener specifications. The following is a suggestion on fastener specifications, including the material, size, manufacturing process, and quality inspection of fasteners, for reference.

1、 Fastener Material Specification

1. Steel specifications: Fasteners are generally made of high-quality carbon structural steel or alloy steel, and should comply with relevant national standards.

2. Stainless steel specifications: Fasteners can also be made of stainless steel material, and the grade and composition of stainless steel should comply with relevant national standards. 304 or 316 stainless steel materials can be selected.

2、 Specification for dimensions of fasteners

1. The dimensions of the fasteners should comply with relevant national standards and design drawings.

2. The aperture and spacing of fasteners should be designed reasonably to facilitate installation and connection. The aperture diameter should generally not exceed 40% of the material thickness, and the spacing should be reasonably designed according to the usage requirements of the fasteners.

3、 Fastener Manufacturing Process Specification

1. Material cutting and processing: During the manufacturing process of fasteners, the cutting and processing of materials must be precise to ensure the dimensional and shape accuracy of the fasteners. The cutting process should comply with relevant standards and requirements.

2. Heat treatment: The heat treatment of fasteners should be carried out according to different materials and requirements to improve their mechanical properties and service life.

3. Surface treatment: Suitable methods such as galvanizing, spraying, etc. should be used for the surface treatment of fasteners to improve their corrosion resistance and aesthetics.

4、 Specification for quality inspection of fasteners

1. Appearance inspection: The fasteners should have a good appearance, without obvious defects such as cracks, damage, deformation, etc.

2. Size inspection: The size of the fastener should meet the design requirements, and the size deviation should be within the allowable range.

3. Material inspection: The material of the fastener should comply with relevant standards and can undergo tensile tests, impact tests, and other inspections.

4. Tensile strength testing: The tensile strength of the fastener should meet the design requirements, and tensile testing can be conducted during testing.

5. Salt spray test: For fasteners with surface treatment, salt spray test can be conducted to evaluate their corrosion resistance.

5、 Specification for fastener identification

1. The fasteners should have clear identification, including information such as fastener type, material, size, etc., to facilitate user identification.

2. The identification should be clear and visible, with good durability, and not easy to fall off or fade.

6、 Specification for the use of fasteners

1. The installation of fasteners should strictly follow the design requirements to ensure installation quality.

2. The use of fasteners should meet the design load requirements and should not exceed the bearing capacity.

3. The fasteners should be regularly inspected during use, and if problems are found, they should be replaced or repaired in a timely manner.

The above are suggestions for the specifications of fasteners. By developing a scientific and reasonable set of fastener specifications, the quality and effectiveness of fasteners can be ensured, and the safety and reliability of construction, furniture, machinery and other fields can be improved.

如您有意咨询请给我们君见玮致电

我们期待您的来电!

If you are interested in consulting, please call us Jun Jianwei We look forward to your call!

咨询电话:18733020585 18508222730

Consultation hotline

止水螺杆使用时的安装间距

我们知道止水螺杆普遍的操作方法是木模板或复合型模版时选用,止水螺杆这一在标准里〈施工工艺〉的规定是常见间隔在400~600,实际的间隔,应当看施工计划设计方案上的要求,由于有的的地区施工单位墙的薄厚非常后,这类状况下止水螺杆间隔就规定就大。实际间隔牵涉到止水螺杆的应用直径、框架柱的高宽比,再开展实际的测算就可以得到。

We know that the common operating method for water stop screws is to use wooden templates or composite templates. In the standard “Construction Technology”, the spacing for water stop screws is usually between 400 and 600. The actual spacing should depend on the requirements of the construction plan design scheme. Due to the extremely thin thickness of the construction unit wall in some areas, the spacing for water stop screws is specified to be large in such situations. The actual spacing involves the application diameter of the water stop screw and the aspect ratio of the frame column, which can be obtained by conducting actual calculations.

pvc管材安装使用方法

PVC管材的安装方法: 1,PVC管在与钢管连接的时候,要先将钢管的连接处擦胶水,将PVC管加热后变软不会烧焦,然后承插在钢管上做降温处理。 2,粘接的时候严禁沾到水,PVC管必须放平在沟内,接头24小时后开始回填,要将管道的四周填紧,接头部位大批量回填。 3,玻璃纤维固化剂配成的树脂溶液浸渍玻璃纤维布之后,均匀缠绕在管道的渗漏出然后固化形成玻璃钢。 4,套补粘接法主要是针对管道小孔和接头的渗漏,选用统一的口径管材将其纵向剖开,然后将管内和外表面打毛,涂胶后在漏水处贴紧。

Installation method of PVC pipes:

1. When connecting PVC pipes to steel pipes, the joints of the pipes should be rubbed with glue first, and the PVC pipes should be heated to become soft without burning. Then, they should be inserted onto the steel pipes for cooling treatment.

2. During bonding, it is strictly prohibited to touch water. PVC pipes must be placed flat in the trench, and backfilling should begin 24 hours after the joint. The surrounding areas of the pipeline should be filled tightly, and the joint parts should be backfilled in large quantities.

3. After the resin solution prepared with glass fiber curing agent is impregnated with glass fiber cloth, it is evenly wrapped around the leakage of the pipeline and then solidified to form fiberglass.

4. The patching and bonding method is mainly aimed at the leakage of small holes and joints in the pipeline. A unified caliber pipe material is selected to longitudinally cut it open, and then the inner and outer surfaces of the pipe are roughened. After applying glue, it is tightly adhered to the leaking area.

钢筋连接套筒和钢筋接头的使用安装方法

一、钢筋连接套筒和钢筋接头的使用安装 1、钢筋就位:将丝头查验合格的钢筋搬运至待联接处。 2、接头拧紧:运用扳手或管钳等东西将联接接头拧紧。 3、作符号:对现已拧紧的接头作符号,与未拧紧的接头区分隔。 4、施工查验:对施工完的接头进行的质量查验。 5、绑扎其它钢筋。 钢筋接头加工的技术是需要十分慎重的进程需要的,我们可以经过比较其他加工技术而言,钢筋接头的技术进程是十分慎重的。

1、 Use and installation of steel bar connection sleeves and steel bar joints 1. Steel bars in place: Transport the steel bars that have passed the wire head inspection to the joint to be connected. 2. Joint tightening: Use a wrench or pipe wrench to tighten the joint. 3. Mark: Mark the joints that have been tightened and separate them from the area of the joints that have not been tightened. 4. Construction inspection: Quality inspection of joints after construction. 5. Bind other steel bars. The technology of processing steel bar joints requires a very cautious process, and we can compare it with other processing technologies. The technical process of steel bar joints is very cautious.

钢筋马镫是做什么用的?

一、提高施工质量 铁马凳的采用,对建筑施工来说,是一种施工技术,因产品为工厂标准化、规格化生产,故其质量比人工制作的马镫更为标准,更加控制板楼下层钢筋保护层的标准性,并有效控制了上下层钢筋的间距。而且通过支架的使用,便于工地施工管理的规范,减少施工随意性。 二、提高施工效率 与传统人工工地现场制作的马镫相比,铁马凳因产品轻巧,安装简便,易于定位,从而减小施工人员劳动强度,通过实际使用情况测算,平均提高现场钢筋施工效率20%左右,在加快了钢筋混凝土施工进度的同时降低了施工成本。并且减少了工地的焊接,有利于提高项目施工的安全性。 三、降低施工成本 铁马凳的使用不仅有效控制工地废料的产生(包括工人现场制作马镫的认为损耗),而且减少了工人现场加工量,节约了工地现场用电量,很大程度降低了生产成本。并且我公司的产品价格比施工现场所用废钢筋制作的铁马凳节约成本30%左右,比用成品钢筋制作的马镫节约成本50%左右,直接降低施工成本。

1、 The use of iron horse stools to improve construction quality is a construction technology for building construction. As the product is standardized and produced by the factory, its quality is more standardized than that of manually made stirrups, which better controls the standardization of the protective layer of the lower steel bars in the slab building and effectively controls the spacing between the upper and lower steel bars. Moreover, the use of brackets facilitates standardized construction management on the construction site and reduces the randomness of construction. 2、 Compared with traditional manual on-site production of stirrups, the iron horse stool reduces the labor intensity of construction personnel due to its lightweight, easy installation, and easy positioning. Based on actual usage, it increases the on-site steel bar construction efficiency by an average of about 20%, accelerating the progress of reinforced concrete construction and reducing construction costs. And it reduces welding on the construction site, which is beneficial for improving the safety of project construction. 3、 The use of iron horse stools to reduce construction costs not only effectively controls the generation of waste materials on the construction site (including the perceived loss of stirrups made by workers on site), but also reduces the on-site processing volume of workers, saves electricity consumption on the construction site, and greatly reduces production costs. And our company’s product price saves about 30% of the cost compared to the iron horse stool made of waste steel bars on the construction site, and about 50% of the cost compared to the stirrup made of finished steel bars, directly reducing construction costs.